Exploring the Legacy of Magnet Drill in Iran since 1965

RR

www.magnetdrill.comIntroduction to Magnet Drills in Iran

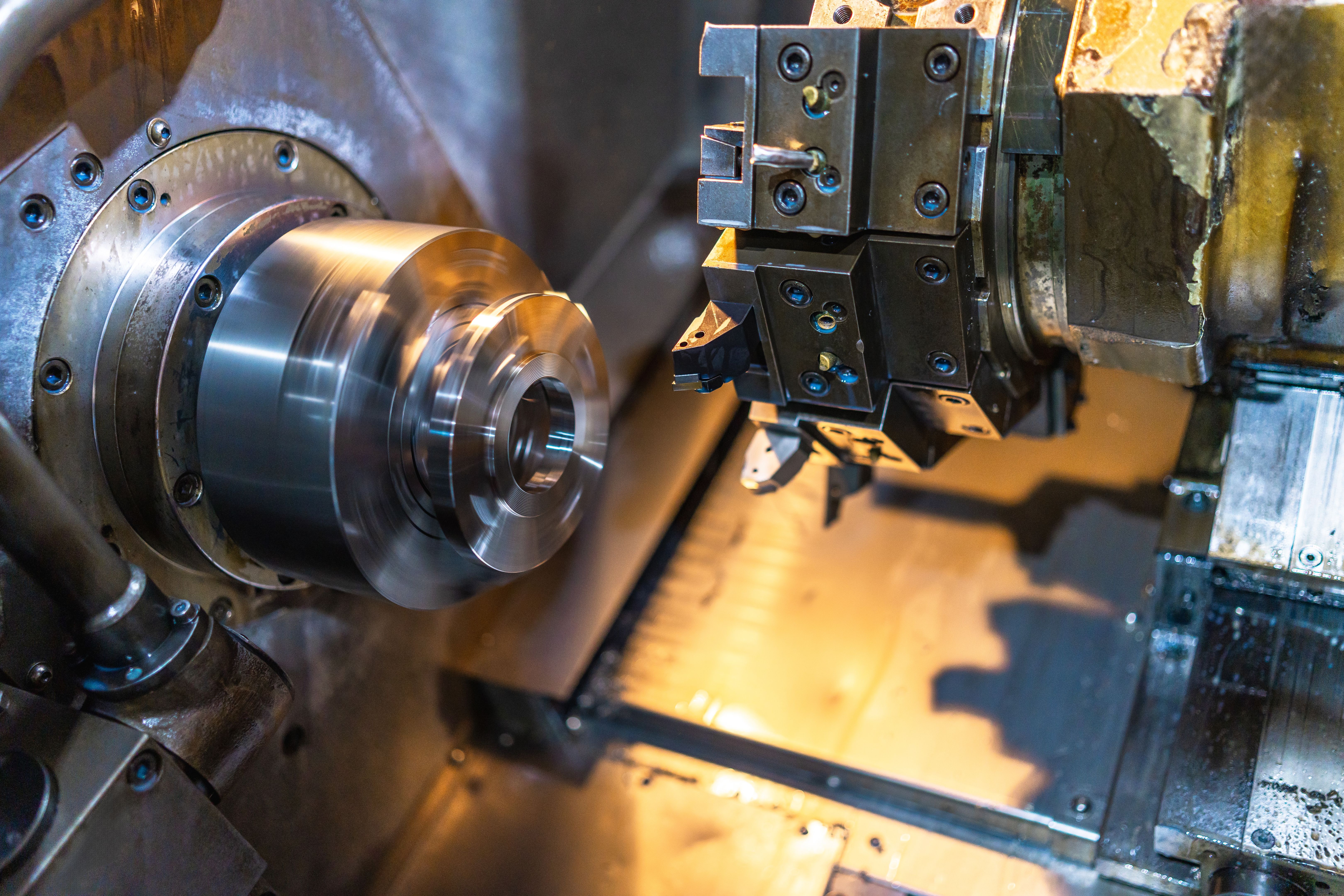

The introduction of magnet drills to Iran in 1965 marked a significant turning point in the country's industrial landscape. These powerful tools, known for their precision and efficiency, quickly became indispensable in various sectors, including construction, manufacturing, and infrastructure development. Over the decades, the legacy of magnet drills has been characterized by technological advancements and widespread adoption.

The Early Adoption and Impact

In the mid-1960s, the arrival of magnet drills in Iran coincided with a period of rapid industrialization. Initially imported from Western countries, these tools were embraced for their ability to perform heavy-duty drilling tasks with unmatched accuracy. This early adoption facilitated the growth of local industries, enabling them to undertake more complex projects and improve overall productivity.

Magnet drills quickly became a staple in the construction industry. Their capability to create precise holes in steel and other metals was particularly beneficial for the burgeoning infrastructure projects at the time. This efficiency not only sped up construction timelines but also significantly reduced labor costs.

Technological Advancements Over the Decades

As technology progressed, so did the features of magnet drills available in Iran. The initial models were relatively basic, but over time, advancements such as variable speed controls, improved magnetic adhesion, and enhanced portability were introduced. These innovations allowed for more versatile applications and contributed to the continued popularity of these tools across various sectors.

Moreover, domestic manufacturers began producing magnet drills locally, which spurred further innovation and customization to meet the specific needs of Iranian industries. This not only reduced dependency on imports but also fostered a sense of national pride in homegrown engineering capabilities.

Current Applications and Industries

Today, magnet drills are extensively used in multiple industries across Iran. In the construction sector, they are indispensable for tasks such as installing steel frameworks, bridges, and high-rise buildings. The manufacturing industry utilizes these drills for precision work in automotive and machinery production.

- Construction: Essential for structural steelwork and infrastructure development.

- Manufacturing: Utilized for precision drilling in production lines.

- Energy Sector: Used in oil and gas exploration and maintenance.

The Role of Education and Training

The effective use of magnet drills requires a skilled workforce. In response to this need, vocational training programs have been established across Iran to equip workers with the necessary skills. These programs focus on safe operation practices, maintenance techniques, and advanced drilling methods, ensuring that operators can maximize the potential of these powerful tools.

As a result, there is a growing pool of skilled professionals who are adept at using magnet drills across various applications. This emphasis on education not only enhances safety standards but also improves overall efficiency in projects involving these tools.

The Future of Magnet Drills in Iran

Looking ahead, the future of magnet drills in Iran appears promising. With ongoing investments in infrastructure and industry, the demand for these tools is expected to remain strong. Additionally, continued technological advancements promise even greater capabilities and efficiency improvements.

As Iran continues to modernize its industrial base, magnet drills will undoubtedly play a crucial role in supporting this growth. Their legacy since 1965 is a testament to their enduring value and adaptability in an ever-evolving industrial landscape.